Some Heavy Machinery!

Well Hello There Fellow Technicians And Hivers!

It's been quite some time since I last worked one of these and by the looks of it they might be coming in full steam again!

Jokes aside these big beastly machines are sometimes a headache to work on and the reason for that is that they are old so when one thing is fixed the next will break because of the extreme performance the new parts give. It's somewhat weird actually.

This was a fairly easy one, for now though. All we had to do for the day was to fit a new clutch and then fit the rebuilt transmission. They have sent the vehicle in for repairs at some other workshop and they rebuilt the motor and the transmission but they messed up horribly. When they rebuilt the transmission they swapped the fourth and fifth gears with each other and this means that when ever you want to select fourth gear you need to select it at 5 on the gear lever and vica versa for the fifth gear.

Hella messed up, I wonder what they told the police when they came to fetch the vehicle?

"Uhhhhh, So you'll notice that the fifth gear and fourth gears have swapped places, so you drive like this now!"

Can you imagine?!

Here She Is!

Don't mind everything that is strewn about at this point we were already busy with it and it was already a mess, these things tend to have that effect so whenever I'm done using a tool I put it back or anything in general, if I opened up a box and it needed to be thrown away I did it straight away because after an hour of work up and down in and out things really get messy!

And when things get messy it can turn into a shit show real fast, that and your morale takes a knock! It isn't any fun working in a dirty area!

Anyways, let's see if we can get her purring again!

Certainly Out Of The Ordinary!

Well, this is going to be some muscle exercise!

Before we can really go on doing anything at all we need to fit the Fly-wheel and Clutch first, imagine fitting the transmission and forgetting that! (Oh, side note. I never checked if the release bearing was fitted onto the transmission and when it was already against the motor when I realized this. Luckily my old man had my back!)

Would you believe me if I said that the pressure plate of the Clutch weighs more than the Fly-wheel or well it does feel like it, I don't actually think it weighs more though.

That's not the only challenge though, there was also the problem of fitting those heavy pieces of metal! Ahhhh who am I kidding I'm a man I can do this no problem!

I've Never Quite Seen This!

Now since the other shop already worked on this vehicle mostly everything is fitted new, which is somewhat of a surprise hey.

Although bossman said we fit our own new parts because frankly I don't want to remove this transmission again just for a simple bearing pull!

Now what is odd with this one is that the bearing was somewhat loose and for a pilot bearing, well I've never seen that! I managed to pull it this far out with my fingers and then I got the puller just to get it out, but I barely touched the puller and it came crashing down!

I'm glad because I thought, nah damn this is going to be one hell of a big struggle to get it out! Turns out not!

Here comes the heavy lifting!

I've fitted quite a few of these in my time but this one somewhat broke me, not in a physical sense but more in a mental sense. When I fitted the Fly-wheel to the crank I had to find the correct sequence of holes, they need to line up.

Now lining that heavy disc up isn't that big of a problem, you just had to keep it there. But the keeping it there wasn't the problem, the problem was that when I pushed it against the crank it bit down and I couldn't get it to turn and no matter what I tried nothing would work!

I thought I'll be stuck here the whole day!

Gladly, this wasn't the case!

Let's Get Her In!

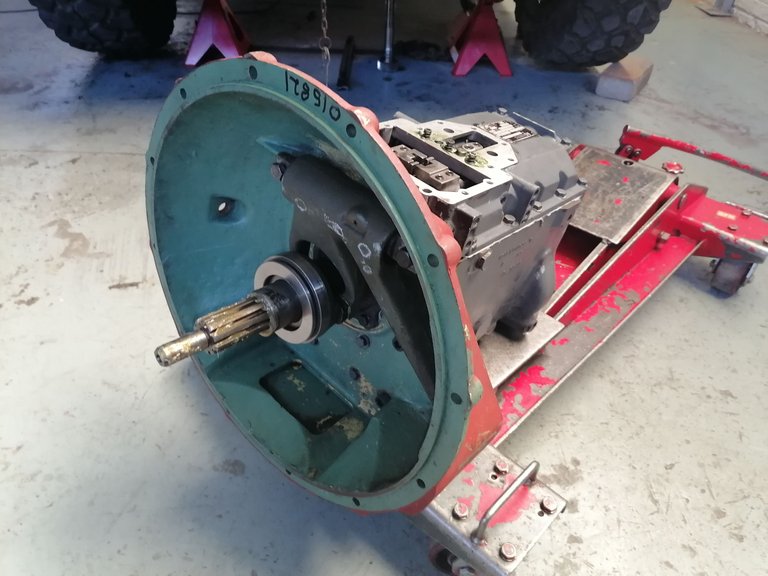

Now the time has finally come for this ironically small transmission to be fitted back into that gigantic piece of metal.

That was one thing that I couldn't wrap my head around when I started with this job. It was the fact that gears were so much smaller than I thought it would be at first and it blew my mind how those small fragile things can take such high load and torque and it can really take a lot of punishment!

Transmissions are underrated!

Take this one for example, this thing needs to pull eight tons and that's not including a full diesel tank and eight men fully equipped with gear!

Hectic shit!

I think this sums up how small it is!

Now don't for one moment think that this small thing doesn't weigh that much! It does and the gears inside are real chunky stuff!

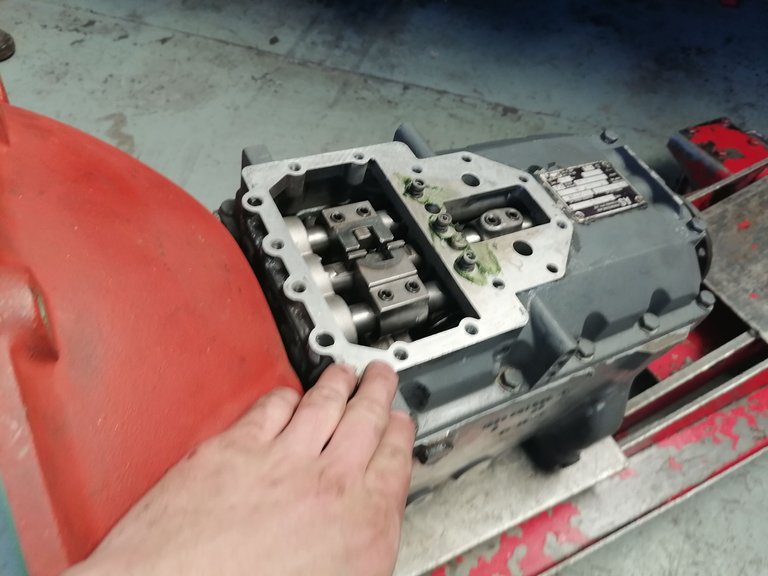

Okay so you want to ask why is the top of the transmission still open? Well the answer is very simple and that is because it has a huge tower that is fitted on top of it and you've got to remove it before you can remove the transmission! The same with fitting it back in.

It's a hassle and one that I ain't very fond of.

Finally We've Reached A Turning Point!

So we're more than half way done with what needs to be done on this vehicle!

I have to say that these are one of the easiest transmissions to fit out there!

Well you might ask why the transmission is a two tone thing, well we bought one out from a scrapyard because the availability on parts with these are beyond scarce. We can import them from America but what would that not cost!

We decided that we're not going to rebuild the old transmission because we had no idea what more problems they might have added in the rebuild when they were busy with it!

At the end of the day we have a whole transmission for spares, so it's not really a loss.

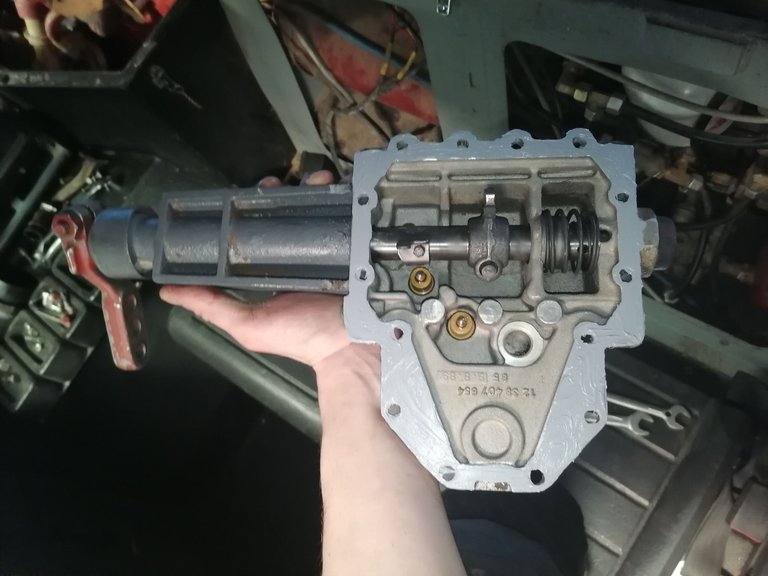

The Tower In Hand!

Now that the transmission is fitted back it was time to add The Tower. Now it's not actually a tower but we refer to it as such. It's nothing more than a fancy name for the gear selector shafts.

Before I can fit it back I need to make sure that all the indents are still inside the transmission and they were, thankfully! I would have slightly crapped myself if they weren't because I left it open during the night, last night. Then I had to add some silicone sealant and somehow wiggle that huge tower into place without smudging all of the sealant off! We do need it to seal off right!

There Was Still Work Left!

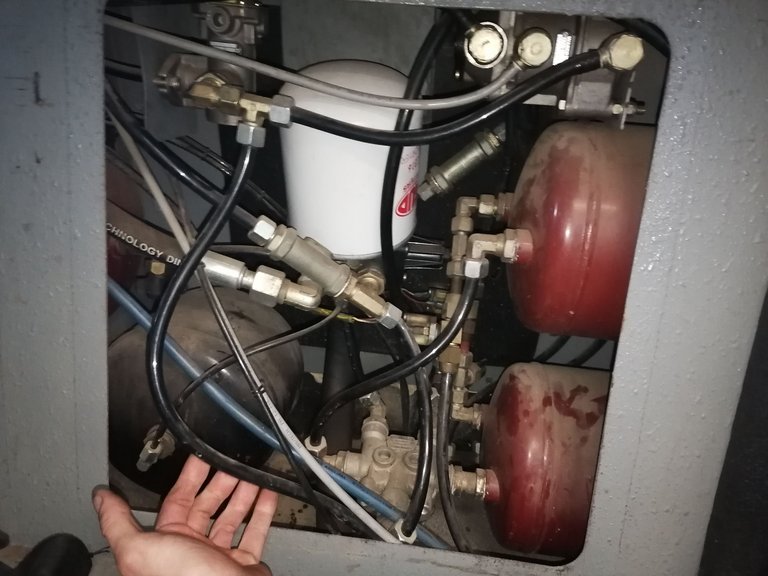

The previous "Nyala" we worked on we had to fit new air pipes into the whole vehicle, meaning pull out all the old ones and fit some new pipe in! This was a real mission to say the least! We spent three days on that because as soon as the new pipes were fitted and the pressure built up some old pipe somewhere popped again!

Now since we've done such a great job with that vehicle they decided to start sending them to us for those problems. That was all they needed to be in a top notch condition! Remember everything on this vehicle works with air and without the air it won't even move because it needs air to release the brakes.

Dated 21/09/2023

Connecting the people of #HIVE across South Africa. #hive

Congratulations @technicalside! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next payout target is 13000 HP.

The unit is Hive Power equivalent because post and comment rewards can be split into HP and HBD

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Hello friends, Bossman is right, you have to put everything back together, you have to make sure that all the pieces fit well, because the truth is, as you say, it is a beastly transmission, it is painful.

That due to a small detail the entire transmission has to be dismantled again, greetings.

Yeah it's a mission hey! Luckily the small fault wasn't ours! If it was and I had to take it out again for such a small problem... well I can't say I would have been happy about it!

I wonder why the other workshop didn't offer to fix the problem because they would have been blacklisted now and they won't get anymore government work, for a while at-least.

It's so much easier in Car Mechanic Simulator when you can just click on the part and it comes off!

I hope you get to take this thing for a little joyride when it's all done. Stop over at a friend's house and give them a little heart attack.

Hahaha of-course it is! Mind you I enjoyed that game a lot! Nice to build up in the game!

Might even be some sort of plan! Rock out at their houses with the sirens and lights on! Laughs they are beastly machines but they aren't very fast!

Thanks for stopping by!

!PIZZA

Wow! let's hope you can soon finish what is missing and be satisfied.

We did manage to fix the air leaks on the machine, ironically the shop that rebuilt the motor, damaged the air pipes coming from the compressor when they reinstalled the motor.

All fixed now and heading to the auto electrician on Monday!

Thanks for stopping by!

$PIZZA slices delivered:

@technicalside(1/5) tipped @winstonalden