It Ain't A Day If It Wasn't An Audi!

Well Hello There Fellow Technicians And Hivers!

You know we can go as far and say that if we didn't work on a Volkswagen or an Audi for that matter, then the day wasn't a good one! I really don't think there is a day that ever goes by where I don't work on either one!

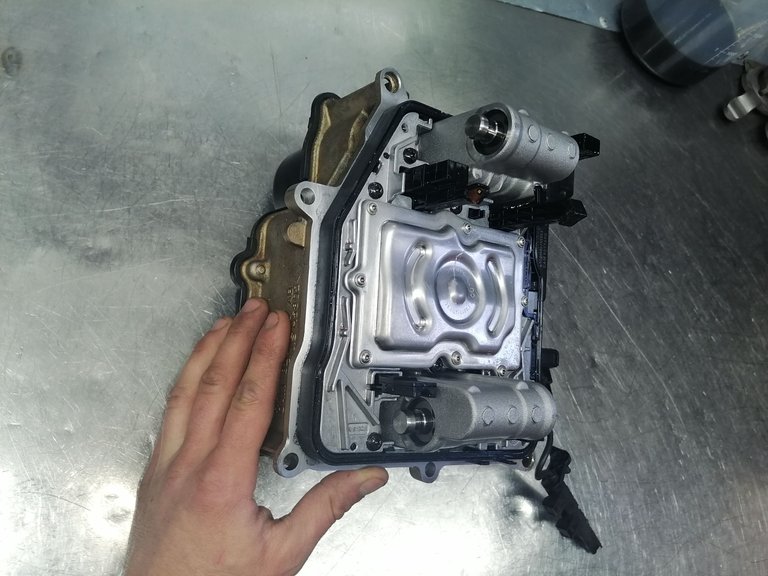

Yes we are here once again with another Megatronics to slap together! This one is somewhat odd in the fault side. The faults it's giving doesn't really correspond with what the vehicle is doing and somehow we managed to get it driving last week but coming back to work today we wanted to start the vehicle and it had nothing. It started up alright but it doesn't want to engage the gear and drive forward or backwards for that matter!

So we decided to pull the entire transmission and rebuild the megatronic along with a clutch replacement.

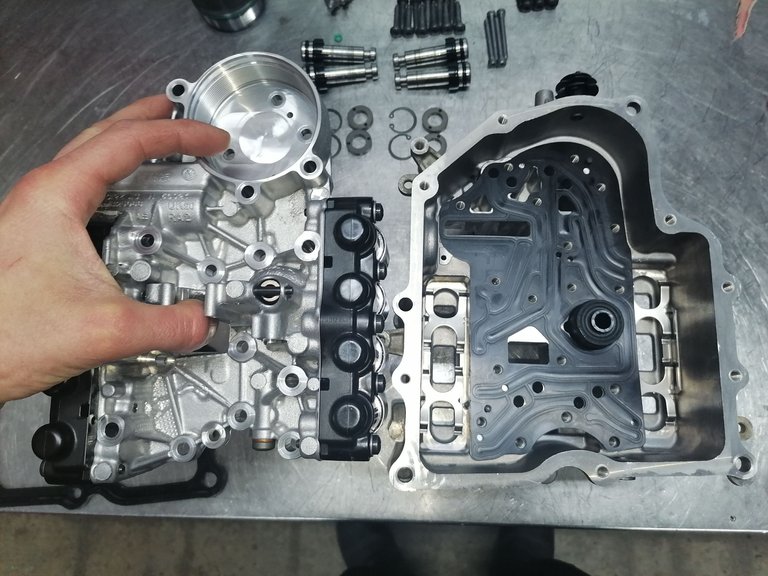

I barely started tearing the Megatronics down when I saw some troubling and puzzling things!

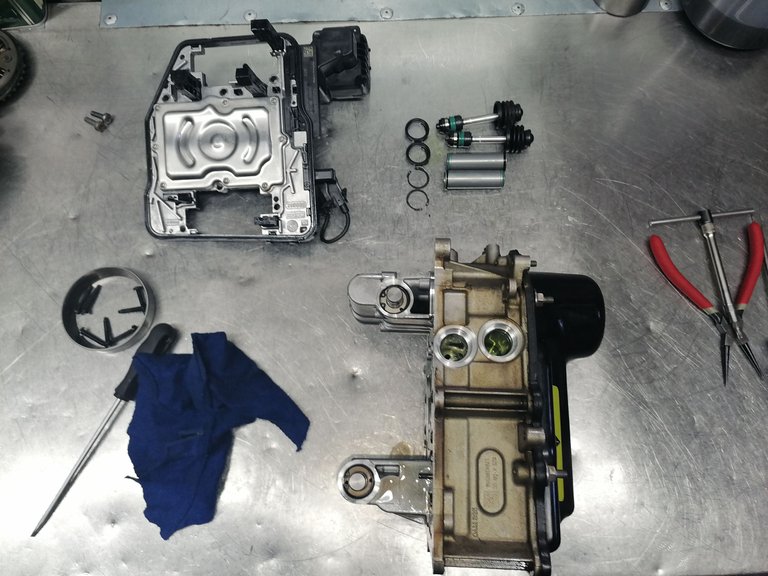

Inside the pistons that work on the clutch as you drive, they engage and disengage. In the cylinders that those pistons run in I found some pieces of plastic that I have absolutely no idea where it might have come from!

I'm saying that I have no idea because I tore down the entire Megatronic and I've still not found anything that was broken inside that could result in the pieces of plastic that I've found.

What I can't wrap my head around is the fact that all of those plastic pieces are grouped together in only one of the two piston cylinders.

Which begs the question as to why there isn't any in the other cylinder? I suppose it doesn't really matter but it matters to me because I have to know why it failed and why only one piston gets clogged up?

At the current standing we can't even explain what happened to the customer, other than the fact that it's losing pressure inside the Megatronics which makes a lot of sense since those plastic pieces can really obstruct pressure and flow in the megatronics system.

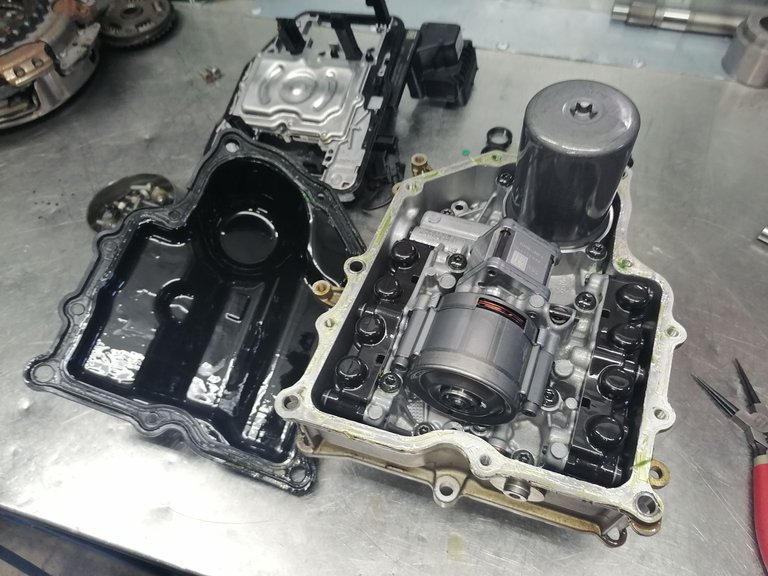

It Looks Fair On The Inside.

The inside where the oil is held in looks very and I mean very good and clean! It's almost as if this Megatronic has been opened up recently, although most of them always look clean. Which also begs the question why does it tend to break?

We're not going to be too worried about keeping things clean, I will be pulling everything through a proper washing!

I have one more place to check for small parts that might be caught in the channels through which the oil gets pumped. First we have to remove all of the goodies on the actual block of the Megatronics and only then can we start removing the bolts that keeps it in place.

Something important to keep in mind is that when unbolting these bodies from the casings you have to give each bolt some slack and only then can you completely remove them all. It's almost as if the block cracks if done differently. I haven't had it yet but I know if it.

I wonder when I'll be the one making that mistake.

This is definitely really weird, I found pieces of plastic in one of the pistons but over here we have no sign of plastic pieces but it's even worse! Over here we have metal shavings which is much much worse than plastic pieces.

I suppose we will have to scrap the block on this one and replace it with another one just to be certain.

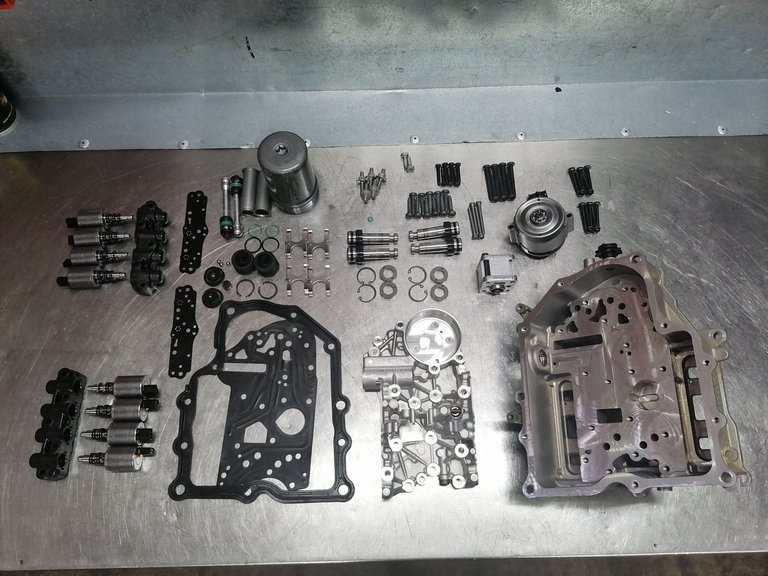

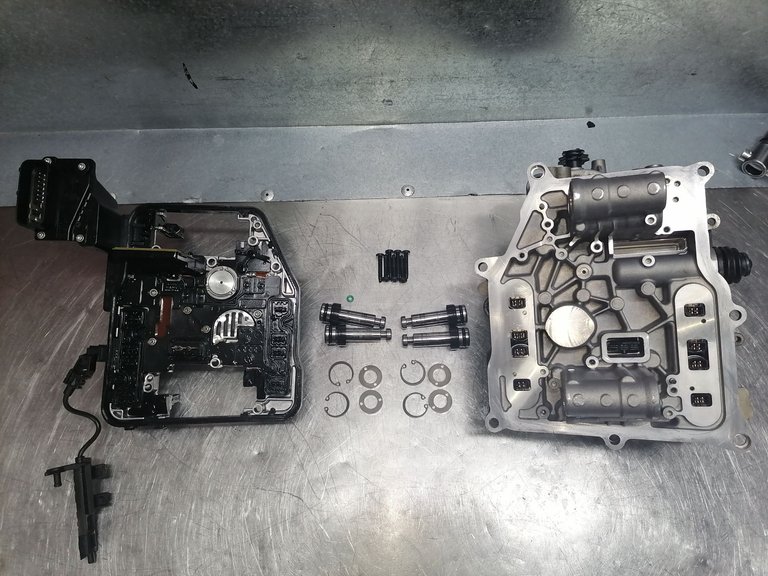

Cleaned Up And Neatly Organized!

Now this was a whole damn mission on its own!

Believe it or not the teardown on these takes about three to four times longer than the build up, the build up's are astonishingly fast given how long we teardown on these!

I think what takes up the most time on a teardown would be the fact that I have to wash and dry everything off, most people would skip that but I just can't.

I think it's time for me to take a break! Laughs Bossman ordered himself an Iced Coffee and well it's not what he thought it was so I told him well I know what it is and I want it!

I heard no objections, so I claimed it!

Couldn't ask for a better refreshment myself!

It Really Is A Fast Slap Together.

I didn't even bother getting all the steps I went through to get to here but let's say that you've got about two or three separate sections to build and then assemble everything together. It's really fast, as I said it takes me longer to teardown than to build.

I give credit to me doing hundreds of these, some people might not slap them together as fast and you know what that's even better. Less room for error right.

I had to share this.

This was once a tool I feared, not really feared but I preferred not to use it. That isn't the case as of lately, I always use it on every valve body I build. It only goes down to 10 Nm Torque and most of the valve bodies are actually torqued around 7 to 9 Nm Torque but for some reason this dial can go below the 10 Nm torque mark. It is in spec for those wondering, we did test it to see if it gives the torque settings on the dial.

But safe to say that I've met a new friend!

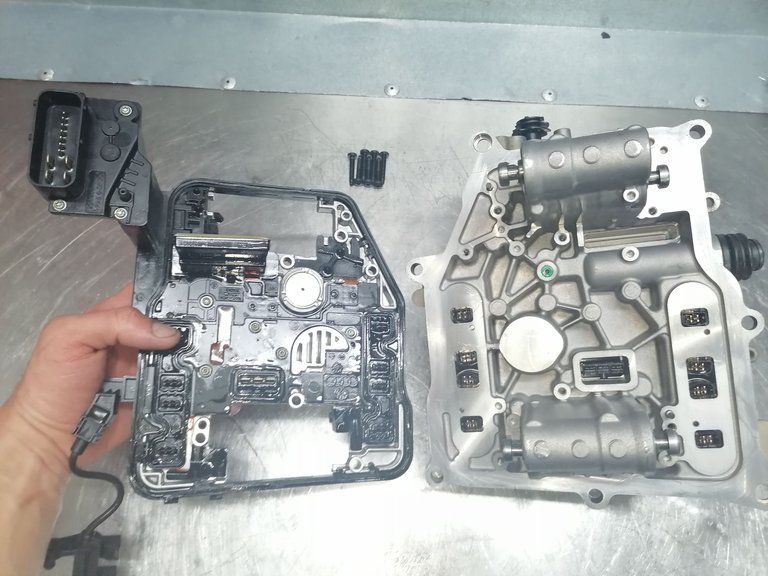

I'm almost there, see even I still do new things on everyday things. See those last four pistons there, those are what is actually selecting the gear inside the transmission. Now we've never had any problems with those before but we do get parts for them inside the service kits now so. Let's fit them in shall we?

Something I've never done!

It Looks Worse Than It Is.

Really it does though!

Those are just marks that's all they really are, they aren't worn into the metal they are just surface marks from moving up and down. We don't get new pistons inside the service kits, only the seal and the o-ring and that is all.

We then remove the old seal and o-ring and then we give it a light polish with some very very very fine grit paper, it must be more than 2k perhaps even 3k.

I barely polished it and the marks came off which is a good feeling in itself!

Dated 04/09/2023

Connecting the people of #HIVE across South Africa. #hive

Congratulations @technicalside! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 1000 posts.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Check out our last posts:

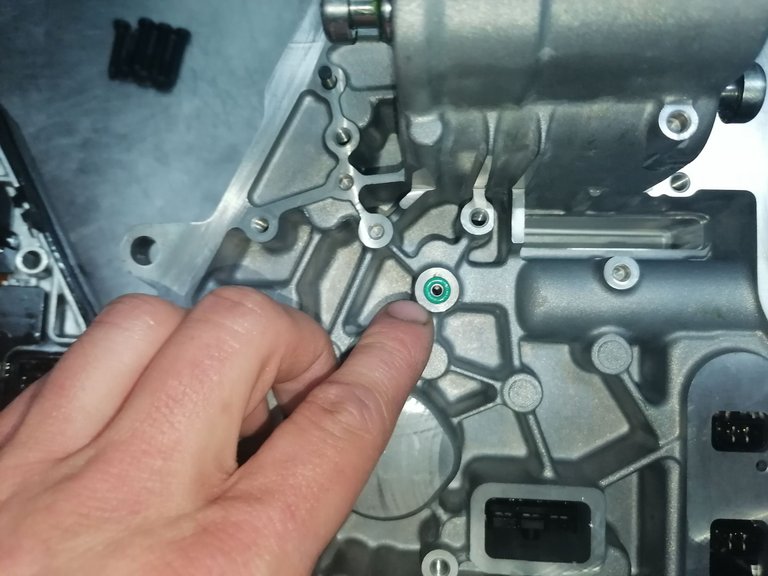

What's so important about the green o-ring?

Love reading about these teardowns btw.

That whole mega tronic bolts onto the transmission but that piece and the transmission each have its own oil. Now since you bolt it to the transmission forgetting that seal would cause all the oil of the megatronic to be pumped into the transmission.

It's only a liter of oil but it's quite expensive.

Es es el problema de las herramientas mecánicas y eléctricas que las causas del problema no tiene nada que ver con las fallas que presentan entonces el carro esta en un dilema si servir o no servir jejeje. Gracias por compartir tu blog