What Are PDLLA Microspheres?

In the field of biomedical materials, PDLLA microspheres (poly-D,L-lactic acid microspheres) have emerged as a focal point in both research and industrial applications due to their biocompatibility, controllable degradability, and multifunctional application potential. This article provides a comprehensive analysis of the core value of this biomedical polymer, covering its definition, properties, application scenarios, and future development directions.

I. What Are PDLLA Microspheres?

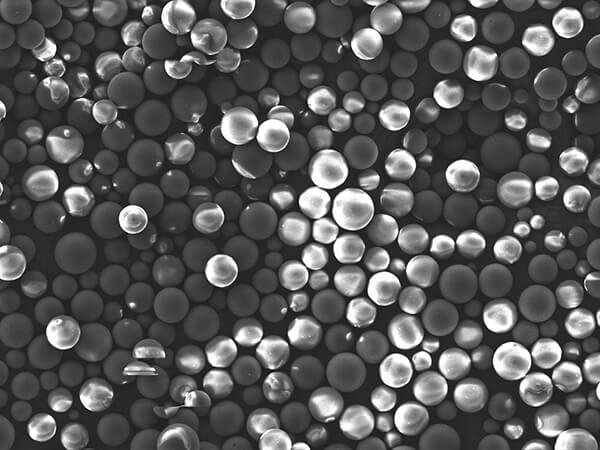

PDLLA (Poly-D,L-lactic acid) is a random copolymer composed of D-lactic acid (D-LA) and L-lactic acid (L-LA), and belongs to the class of biodegradable aliphatic polyesters. Its microsphere form is prepared through specialized techniques such as emulsion-solvent evaporation or electrospinning, with particle sizes typically ranging from 10 to 100 micrometers. These microspheres feature a high surface area and porous structure, offering distinct advantages in drug delivery, tissue regeneration, and aesthetic dermal fillers.

II. Four Key Properties of PDLLA Microspheres

Biocompatibility and Safety

Upon degradation in the body, PDLLA microspheres break down into lactic acid, which is further metabolized into water and carbon dioxide. This process leaves no toxic residues, making them suitable for long-term implantation and injectable medical products.

Controllable Degradation Profile

The degradation rate can be tailored by adjusting molecular weight, crystallinity, and monomer composition, ranging from several months to years. For example, dermal fillers are often designed with a degradation cycle of 12–24 months to align with the natural collagen regeneration process.

Multifunctional Drug Loading Capability

The porous structure enables high-efficiency loading of drugs, growth factors, or genes, allowing for controlled and targeted release. In cancer treatment, for instance, PDLLA microspheres can deliver chemotherapeutic agents directly to tumors, minimizing systemic toxicity.

Tunable Mechanical Properties

By modifying polymerization methods (e.g., block copolymerization, surface modification), the mechanical strength, hydrophilicity, and degradation rate of the microspheres can be optimized to suit complex applications such as orthopedic scaffolds and artificial blood vessels.

III. Three Major Application Areas of PDLLA Microspheres

Aesthetic and Regenerative Fillers

PDLLA microspheres play a prominent role in regenerative aesthetic products such as "baby face" injections. They stimulate fibroblasts to produce collagen, restoring facial volume and improving skin elasticity. Compared to traditional PLLA, PDLLA fillers offer a faster degradation rate, ideal for users seeking a gradual and natural enhancement.

Drug Delivery Systems

As carriers, PDLLA microspheres can encapsulate anticancer drugs, antibiotics, or vaccines, extending efficacy through sustained release. Studies show that drug concentrations at tumor sites can reach levels more than ten times higher than those achieved through oral administration.

Tissue Engineering Scaffolds

In composite nanofiber membranes or 3D-printed scaffolds, PDLLA microspheres provide mechanical support while promoting cell adhesion and proliferation. For instance, CHOL-g-PDLLA/PDLLA composite scaffolds have demonstrated high porosity and bioactivity in bone defect repair applications.

IV. Future Development Directions for PDLLA Microspheres

Precision Modification Techniques

To improve hydrophilicity and prolong in vivo circulation, researchers are developing amphiphilic copolymers such as PEG-PDLLA. By introducing hydrophilic groups into the polymer chain, these modifications enhance hydration and biocompatibility, optimizing drug delivery performance.

Intelligent Responsive Design

Incorporating materials responsive to pH or temperature can enable on-demand drug release. For example, in the acidic microenvironment of tumors, drug release can be triggered explosively to improve therapeutic outcomes and minimize damage to healthy tissues.

Integrated 3D Printing Applications

Taking advantage of PDLLA microspheres' high plasticity, researchers are developing customized bio-inks for printing complex organ models or personalized implantable devices.

V. Conclusion

As an innovative representative of biomedical materials, PDLLA microspheres are driving the medical and aesthetic fields toward greater precision and minimally invasive solutions. With continued advancements in synthesis techniques and clinical research, their application boundaries are expected to expand further, offering improved solutions for human health