Installation and commissioning of a 30 hp submersible motor and pump.

Good afternoon, dear community, after such a long time of absence in the area of engineering, I begin this 2024 with a topic of great interest when we find communities that do not have drinking water services, due to an infinite number of factors.

In the area of civil engineering our training in the Andes was comprehensive, whether in the area of hydraulics, construction and roads.

Areas of great interest in the development of my training as an engineer, days ago I had the opportunity to witness an installation of engine and pump to pour drinking water to a vulnerable community in the state of Trujillo Venezuela, known as Santa Cruz.

In order to put such a majestic installation into practice, a manual calculation must be carried out, depending on the flow rate, in sanitary installations, what we call the hydraulic system.

I remember as a student, they come to my head by the amount of interactions that must be executed to reach the exact diagnosis, depending on the type of engine and pump to be used.

I was present thanks to some colleagues who allowed me to live the moment, which I miss so much.

Population: 2000 thousand inhabitants.

MATERIALS AND EQUIPMENT:

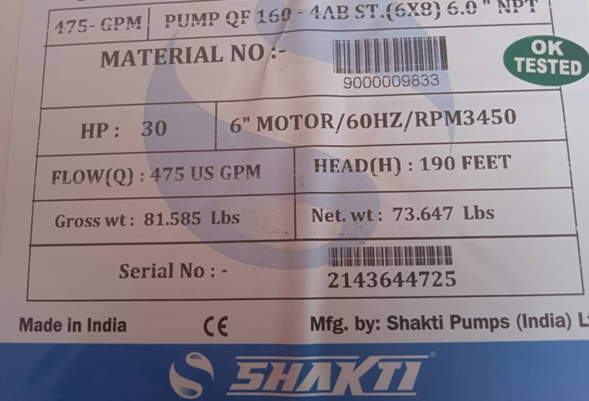

-30 hp submersible motor.

Features

-5-stage vertical submersible pump for 30 hp motor.

-80 metres of three-phase flat cable for submersible pump, 600 volt, 65 degree temperature, 3x8 gauge.

-Crane.

-Vehicles.

TOOLS:

-48 inch pipe spanner.

-Chain spanner for 6-inch pipe.

-Pliers.

-Screwdrivers.

-Pipe holder.

-10 pvc pipes of 6 inches, length 6 metres.

LABOUR:

-Hidroandes company technical team.

The day begins as follows:

Having located each of the equipment and materials, we proceed to the destination of the installation from the well to the storage tank there are 2 kilometres, to make a splice with the motor driver and the submersible cable, the kit was placed to splice the 3m resin and was left to dry for about 7 hours.

On this route, installation criteria were shared.

Then the pump was coupled to the motor as shown on the cover, with the help of the technical staff and workers, the equipment began to be introduced into the well with a depth of 80 metres with the support of a crane, pvc pipes of 3 metres each with a diameter of 4 inches were placed.

The pump and the motor coupled to the 6-inch PVC pipe are carefully introduced into the well and the 3x8 cable is also introduced.

This procedure is repeated until the last pipe is completed, being 10 pipes of 6 meters each, installing 60 meters.

Once the 6 metres had been installed, the discharge was coupled to the 6-inch iron pipe, allowing the discharge suction to be coupled.

Now, the installation of the 3x8 conductor is made to the board.

The panel allows the submersible motor to operate, using a direct start system with its respective protections.

Once installed, the respective tests were carried out, yielding a flow rate of 25 litres per second.

Once the system was installed, a 400 cubic metre tank was filled to supply the community that had no drinking water service.

Interesting procedure, one thing is theory and another is practice.

Looking forward to other experiences.

The deepl translator was used as my language is Spanish.

Wow that's great there!

Thank you very much, my friend.

Happy evening.

What a great blessing it is to have water, the work was impeccable, the finish, the electricity, everything looks well done, congratulations to the work team.

That's right, water is life.

A lot of hard work was done with qualified people for that.

Thanks for stopping by my friend.

Regards.

What a breakthrough that they were able to replace the submersible pump, it can be seen that the well has depth due to the power of the pump.

That's right, my friend.

A complete team for the well-being of the community.

Water for life! What a great job and you can see that there was a very good logistics, thanks for sharing this content.

Thanks for stopping by my friend.

We did our best to provide the community with its indispensable resource.

Hello friend, what a great job they had to do to be able to solve and give that great benefit to that community, since being without water is the worst thing that can happen and it is incredible how they managed to put it together and have everything turn out wonderfully, it was definitely worth it. all those calculations and now being able to rest easy.

Indeed, water is vital for any action.

With the training of specialists and the state, it was possible to bring this resource to every household.

This is a very beautiful skill. The pumb is really heavy to install and I think this will not be done using hand . All the electric connection look super. Weldone

With the help of manpower together with the necessary machinery it was possible to get this resource to every household.

Thank you for stopping by.

Best regards.

In the photos you cannot see the size of the pump but from the amount of water I can imagine, 25 liters per second is a significant flow.

How interesting to be part of something like this.

Indeed I missed to take a close up of the pump, also you can see in the third picture of the post, the pump when it is coupled with the engine.

It's great to be part of this process.

Thanks for stopping by.

Blessings.